Car Body Parts: Materials and Forming Processes 2024

Combining expertise

As a premiere in 2024, Automotive Circle’s new event Car Body Parts: Materials and Forming Processes combines two of its long-established annual focus conferences in Bad Nauheim, Germany. The former Materials in Car Body Engineering and Car Body Parts / Forming in Car Body Engineering conferences join forces and merge into a two-day congress.

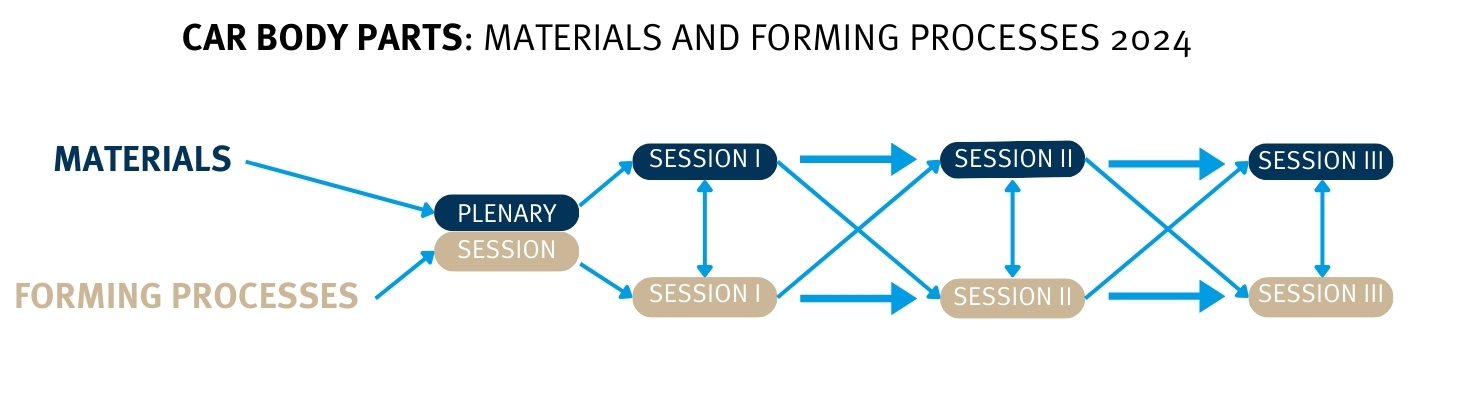

With a mixture of focus contributions in two-fold parallel sessions as well as general-interest plenary presentations, the congress aims to cover both progress in car body materials development and car body part production processes, bringing together the expertise of Automotive Circle’s global network of material experts and forming process specialists.

Overview of parallel Congress Sessions

Congress Program

| Time |

Kursaal |

Spiegelsaal |

| Plenary Session: Minimising the carbon footprint | ||

| 8:00 am | Welcome and congress introduction Dr. Dirk Meine, Automotive Circle, DE |

|

| 8:30 am | The role of sustainable aluminium in car body manufacturing Patrik Ragnarsson, European Aluminium, BE |

|

| 9:15 am | Circular vs extractive steel production: How EAF mills can produce all sheet steel grades Dean Kanelos, Nucor Automotive Group, US |

|

| 9:45 am | Development of low carbon steel sheets for automotive outer panels based on the ‘EAF+BF’ combined process Dr. Jong Myeong Kim, Hyundai Steel Company, KR |

|

| 10:15 am | Meet the Speakers / Exhibition / Coffee and contacts | |

| Circularity: Aluminium | Panel forming: Simulation and quality control | |

| 11:00 am | How to reduce the CO2e footprint of the BIW – Alloy selection for aluminium-intensive vehicles maximizing circularity Olivier Rebuffet, Thomas Payer, Alumobility, BE |

Artificial vision quality control of the entire forming parts production Thomas D´Hautefeuille, Group Renault , FR; Quentin Lecomte, Eines Vison Systems, ES |

| 11:30 am | High recycled content material for performance driven applications Dr. Florian Stadler, AMAG rolling GmbH, AT |

Innovative optical system for surface quality control on formed panel Hubert Lechner, Carl Zeiss Automated Inspection GmbH, DE |

| 12:00 pm | New generation of premium recycling aluminium alloys – The main solution for the true decarbonization of mobility in Europe Ruggero Zambelli, Raffmetal S.p.A., IT |

From stamping to assembly – a comprehensive approach for digital BiW process validation Dr. Gianfranco Ruggiero, AutoForm Group, IT |

| 12:30 pm | Developing high-performance aluminum alloys from varied scrap streams Dr. Stuart Wiesner, Aluminium Rheinfelden Alloys GmbH, DE |

Welding simulation and the influence on tryout Ralf Pfitzenmaier, EDAG PS GmbH & Co. KG, DE |

| 1:00 pm | Meet the Speakers / Exhibition / Lunch break | |

| (Mega)Castings | Press-hardenened steel | |

| 2:15 pm | Detailed description of cast material properties to enable ultimate lightweight design Dr. Christoph Viechtbauer, Nemak Europe GmbH, DE |

-ONLINE- Sustainable lightweight construction for modern car body parts: Trends and challenges in process optimization and manufacturing of automotive components with tailored properties Prof. Marion Merklein, Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU), Institute of Manufacturing Technology, DE |

| 2:45 pm | New high performance structural casting alloy developed by AUDI Dr. Marius Kohlhepp, Audi AG, DE |

Vacuum hot forming press hardened steel with zinc coating Tony An, Pressler Advanced Forming Technologies Co., Ltd., CN |

| 3:15 pm | Meeting tolerance requirements in (ultra) large castings Philipp Hettich, Laubinger + Rickmann GmbH & Co. KG, DE; Martin Hartlieb, Viami International Inc., CA |

The 2nd generation of the multistep hot stamping process Jordi Castilla Moreno, Gestamp Servicios, S.A. , ES |

| 3:45 pm | Meet the Speakers / Exhibition / Coffee and contacts | |

| (Mega)Castings | Press-hardenened steel | |

| 4:30 pm | Fast track for ultra-lightweight megacastings: How to reduce development time by 90% Markus Unruh, Bionic Mesh Design GmbH, DE |

-ONLINE- Coating-free press hardening steels and rapid heating for automotive applications Sarah Tedesco, Ming Shi, General Motors Company, US |

| 5:00 pm | Low Pressure Sand Casting LPSC of complete rear and front underbody (mega)casting parts Dr. Joachim Gundlach, Grunewald GmbH & Co. KG, DE; Kentaro Higaki, Kimura Foundry Co. Ltd, JP |

Application of coated 2GPa press hardening steel on a serial B-pillar for automotive weight reduction Ludovic Dormegny, ArcelorMittal, FR; Ersel Ozden, Toyotetsu, TR; Edip Ozer Arman, Toyota Motor Europe, BE |

| 5:30 pm | 3D core printing: innovative cast components for the body shop of the future Andreas Brenninger, Oliver Pätzold, BMW Group, DE |

Development of element technologies for integrated hot-stamping parts Dr. Masahiro Kubo, Nippon Steel Corporation, JP |

| 6:00 pm | Meet the Speakers / Exhibition / Get together | |

| 7:00 pm | Networking Dinner | |

(Plenary Assembly in room Kursaal)

| Time |

Kursaal |

Spiegelsaal |

| Plenary keynote presentation | ||

| 8:00 am | AI in automotive materials development and application Prof. Dirk Mohr, ETH Zurich, CH |

|

| 9:00 am | Meet the Speakers / Exhibition / Coffee and contacts | |

| Casting developments | Panel forming process developments | |

| 9:30 am | Beyond boundaries – unveiling breakthroughs in vacuum dosing technology for mega & giga foundries Angela Harrison, Meltec Industrieofenbau GmbH, AT |

Meeting tolerance, properties and process efficiency requirements in battery tray and structural extrusions Norbert Meinikmann, Laubinger + Rickmann GmbH & Co. KG, DE |

| 10:00 am | Application of casting aluminum in new vehicle design to increase sustainability decreasing weight Dr. Jacopo Tatti, Stellantis N.V., IT |

Innovative solutions for lightweighting in automotive structures: a comprehensive study on the blow forming of a 5xxx/7xxx aluminum alloy Leonardo Daniele Scintilla, Fontana Group, IT; Ramona Tosone, AMAG rolling GmbH , AT |

| 10:30 am | Digitalization of brownfield high pressure die casting Julian Bargfrede, Technische Universität Braunschweig – Institut of Joining and Welding, DE |

Smart manufacturing redefined: Cloud-driven big data analytics and AI for automotive press shop quality assurance Otto Lampert, iLARIZ GmbH, DE |

| 11:00 am | Meet the Speakers / Exhibition / Coffee and contacts | |

| Steel body concepts | Panel forming process developments | |

| 11:30 am | Combining the Multipart Integration approach with a carbon-neutral steel product offer to diminish the environmental impact of upcoming vehicle models Jessé Paegle, ArcelorMittal, FR |

Applying urethane using additive manufacturing to get better surface quality in autobody panels Donggyun Kim, Hyundai Motor Company, KR |

| 12:00 pm | Materials for battery boxes: a hot topic Carel ten Horn, Tata Steel Netherlands, NL |

New generation line dies with 3D print inserts Bora Tandırcıoğlu, Orhan Bibika, Ford Otosan A.Ş., TR |

| 12:30 pm | Steel-based concept body of future electric SUV Dr. Dae Young Kim, Hyundai Steel Company, KR |

More stability for the forming process in presslines due to precise and process monitored blank lubrication in front of line with Servo-Spray-Technology Leo Sonntag, Amtec Kistler GmbH, DE |

| 1:00 pm | Meet the Speakers / Exhibition / Lunch break | |

| Steel alloy developments | New module concepts | |

| 2:00 pm | Formability characteristics of advanced HSLA steels Prof. Hardy Mohrbacher, NiobelCon BV, BE; Caio Pisano, CBMM Europe, IT |

FlexHyBat – light commercial vehicles body floor concept based on reinforced 3D-roll-formed profiles Dr. Martin Hillebrecht, EDAG Engineering GmbH, DE |

| 2:30 pm | A new AHSS generation combining higher strength with improved forming properties and crash performance Adrian Paton, thyssenkrupp Steel Europe AG, DE |

High-performance long fiber thermoplastic composite compression molding for structural applications Dr. Kristian Seidel, Teijin Automotive Technologies, DE |

| 3:00 pm | Cold rolled martensitic steel 1.5/1.7GPa Grade with excellent flatness / AlSi Coated 1.5/2.0GPa PHS with superior HE resistance and bendability Dr. Jong-Pan Kong, Seongwoo Kim, POSCO Automotive Steel Research Lab., KR |

Hybrid crash reinforcement alternative to metals in EVs sill Sabine Wenig, Sika Automotive AG, CH; Eduard Haberkorn, acs Automotive Center Südwestfalen GmbH, DE |

| 3:30 pm | Kursaal | Plenary Assembly | |

| 3:35 pm | OEM conclusions Members of the Advisory Board on their congress summary and future outlook on Car Body Part development and production |

|

| 4:00 pm | Farewell address and end of the congress | |

Program is subject to change

Status as of: June 6, 2024

Participants

More Information

Participation fee

expired

Participation fee

expired

Participation fee

for registrations received after May 10, 2023

Your Contacts