Joining in Car Body Engineering 2024

EFFECTIVE JOINING – AND DE-JOINING

Optimising second-generation BEV and PHEV car body structures and moving towards a sustainable, carbon-neutral, yet cost-effective production probably are the two main goals in modern car body engineering, and both have much to do with optimised joining technologies and joining concepts. For instance:

- Modern battery case structures are becoming further integrated into crash load paths: How do joining concepts best reflect that?

- Megacastings are intensely discussed: When realised, how are they best joined to the rest of the structure?

- Carbon-neutral vehicle production scenarios need to include intelligent recycling concepts: Joints may need to be easily de-joinable at a vehicle’s end-of-life.

Thus, to discuss latest suggestions for optimal joining solutions, Automotive Circle’s international conference on Joining in Car Body Engineering will again discuss latest progress in all industrially relevant body shop processes with its network of experts, on April 16-18, 2024, in Bad Nauheim, Germany.

Conference Structure

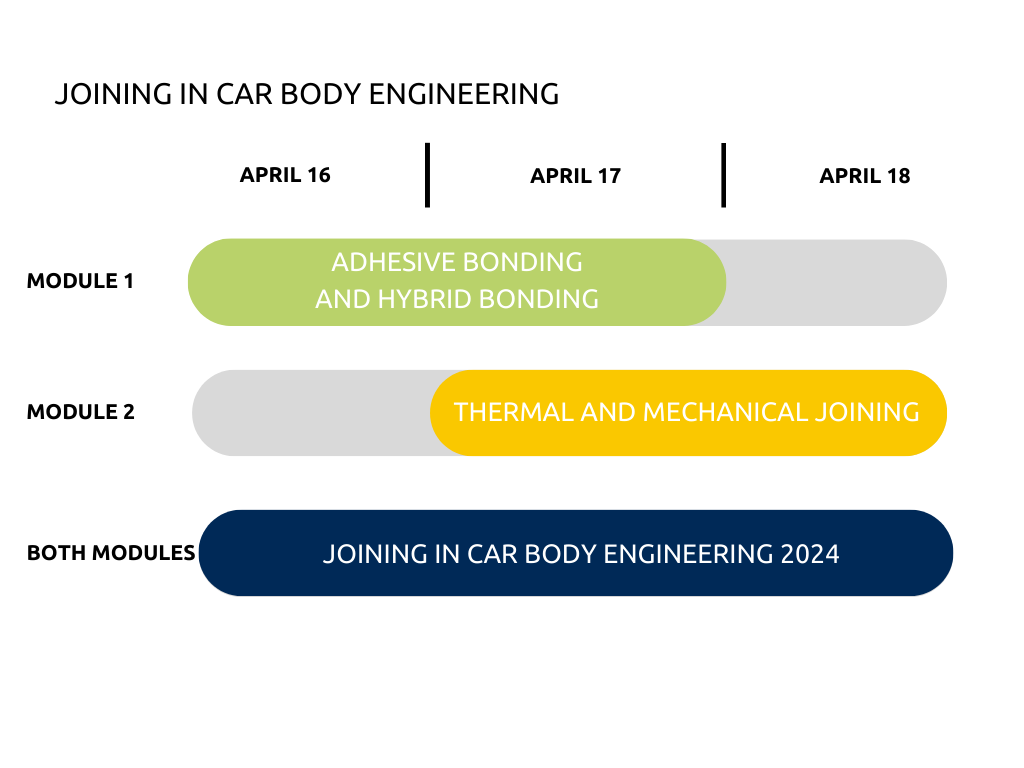

The three conference days consist of two, separately bookable modules:

Module 1, covering progress in Adhesive Bonding and Hybrid Bonding technologies, starts on the first conference day and ends in the early afternoon of the second.

Module 2, covering developments in Thermal and Mechanical Joining technologies, starts in the morning of the second conference day and ends in the afternoon of the third.

The first sessions or the second conference day feature a joint program of presentations for participants of either module, with topics that are presumed to be of interest to all participants, for instance OEM presenting the full joining concept of a recently launched car body project.

Conference Agenda

MODULE 1: ADHESIVE AND HYBRID BONDING

| 8:30 AM | Welcome and conference introduction Module 1 | Dr. Dirk Meine, Automotive Circle, DE |

Advancing structural body shop adhesives |

||

| 8:45 AM | Elementary adhesive bonding for car body construction – an interdisciplinary collaboration | Güven Çelebi, Technische Universität Braunschweig, Institute of Joining and Welding, DE; Konstantin Meglin, GH Induction Deutschland GmbH, DE; David Guitton, Sika Technology AG, CH |

| 9:15 AM | New generation peroxide cure anti-flutter for automotive body shop application | Dr. Alicja Schlange, Mercedes-Benz AG, DE; Florian Lindekugel, Henkel KgaA, DE |

| 9:45 AM | Structural bonding without curing time for direct further processing | Philipp Hug, Collano AG, CH |

| 10:15 AM | New structural body shop adhesives offering superior fatigue durability | Dr. Andreas Lutz, Specialty Electronics Materials Switzerland GmbH (DuPont), CH |

| 10:45 AM |

Meet the speakers | Coffee and contacts |

|

New processes, new applications |

||

| 11:30 AM | Low temperature curing materials as enabler for carbon neutrality and electrification – challenges & solutions | Gurkan Sonmez, Jaguar Land Rover Ltd., UK; Michael Klotz, Henkel KgaA, DE |

| 12:00 PM | Bonding solutions for the battery case as an integrated part of the car body structure | Antonio Voci, Denise Storrer, Sika Automotive AG, CH |

| 12:30 PM | Local thermal conditioning of an adhesive composite to extend the temperature operation range of assembly adhesives | Merlin O. Kapelar, Volkswagen AG, DE |

| 1:00 PM |

Meet the speakers | Lunch Break |

|

Improving adhesion and adhesion mechanisms |

||

| 2:15 PM | Next generation fast cure structural PU adhesives with improved adhesion spectrum to various substrates | Dr. Felix Koch & Stefan Schmatloch, Specialty Electronics Materials Switzerland GmbH (DuPont), CH |

| 2:45 PM | Molecular plasma – solving bonding challenges with solvent-free functional coatings | Kevin Braun, Molecular Plasma Group S.A., LU |

| 3:15 PM | Long-term stabilization of automotive adhesion and interfacial design | Dr. Nao Terasaki, National Institute of Advanced Industrial Science and Technology (AIST), JP |

| 3:45 PM |

Meet the speakers | Coffee and contacts |

|

Towards circular economy (I) |

||

| 4:30 PM | Circular economy – the importance of joining technologies | Dr. Marko Gernuks, Volkswagen AG / Open Hybrid Lab Factory e.V., DE |

| 5:00 PM | Debonding solutions for automotive applications | Dr. Nikolai Kolb, Evonik Operations GmbH, DE |

| 5:30 PM | Towards industrial implementation of on-demand debonding in the automotive industry | Dr. Jeroen Jordens, Flanders Make, BE |

| 6:00 PM |

Meet the speakers & Get together |

|

| 7:00 PM |

Networking dinner Module 1 |

|

MODULE 1: ADHESIVE AND HYBRID BONDING

MODULE 2: THERMAL AND MECHANICAL JOINING

*joint sessions of both modules*

| 8:40 AM | Welcome and conference introduction Module 2 | Dr. Dirk Meine, Automotive Circle, DE |

OEM joining solutions and strategies |

||

| 9:00 AM | Compressed air free body shop | Michael Lang, Audi AG, DE |

| 9:30 AM | Leak tight resistance spot welding of steel battery trays | Maurice Kohls & Johannes Kaptain, Ford-Werke GmbH, DE |

| 10:00 AM | Joining technology in the new Volvo EX 90 – Subsequent discussion at the BIW exhibit on site – | Dr. Marcus Schmidt & Dr. Per Lindahl, Volvo Car Corporation, SE |

| 10:45 AM |

Meet the speakers | Coffee and contacts |

|

Challenging joints |

||

| 11:30 AM | Impregnation and bonding of hybrid wood-based materials in automotive body shell construction | Dr. Moira Burnett, Fraunhofer Institute for Wood Research (Wilhelm-Klauditz-Institut, WKI), DE |

| 12:00 PM | Joining of aluminum UHSS dissimilar combinations by vaporizing foil actuator welding | Prof. Taeseon Lee, Incheon National University, Department of Mechanical Engineering, KR |

| 12:30 PM | Joining solutions for a steel-based battery box cooling unit | Laurent Cretteur & T. Krim, ArcelorMittal Global Research and Development, FR |

| 1:00 PM |

Meet the speakers | Lunch Break |

|

Progress in quality control |

||

| 2:15 PM | New non-destructive measurement approach for the in-line quality assurance of structural bonded joints in car bodies | Christian Gundlach, TU Braunschweig, Institute of Joining and Welding (ifs), DE |

| 2:45 PM | Seamless inspection of surface cleanliness using high-speed laser scanners | Vivien Behrendt, Fraunhofer Institute for Physical Measurement Techniques IPM, DE |

Towards circular economy (II) |

||

| 3:15 PM | Possible future strategy of automobile production – potential of reusing automotive components | Dr. Frank Riedel, Fraunhofer Institute for Machine Tools and Forming Technology (IWU), DE |

| 3:45 PM |

Meet the speakers | Coffee and contacts |

|

END OF MODULE 1 / MODULE 2 CONTINUED

Advanced thermal joining |

||

| 4:30 PM | Predicting and improving the quality of drawn arc welded studs in the car body shop | Daniel Els & Dr. Shahan Tutunjian, BMW AG, DE |

| 5:00 PM | Enhancements and process optimization for drawn arc stud welding | Dr. Christian Reis & Maximilian Braun, Tucker GmbH, DE |

| 5:30 PM | Quality and process improvements by implementing pneumatic equalization and applied integrated actuator in KIA 7th axis welding guns | Johannes Berwanger, Festo SE & Co. KG, DE; Seungho Lee, Kia Motors Corporation, KR |

| 6:00 PM |

Meet the speakers & Get together |

|

| 7:00 PM |

Networking dinner Module 2 |

|

Resistance spot welding development |

||

| 8:30 AM | Thermally decoupled welding insert for multi-material combinations – validation and application at Stellantis | Régis Alain, Gaming Engineering, FR; Michele Maria Tedesco, Stellantis NV, IT |

| 9:00 AM | Use of multi-pulse welding to increase the weldability of ultra-high-strength hot-forming steels | Daniel Kiesow, Volkswagen AG, DE |

| 9:30 AM | Robots data monitoring for spot welding performance | Mihai Radu, Group Renault, FR |

| 10:00 AM | Resistance element welding in serial application – challenges, process advantages and examples | Vitalij Janzen, Arnold Umformtechnik GmbH & Co. KG, DE |

| 10:30 AM |

Meet the speakers | Coffee and contacts |

|

Advanced mechanical joining |

||

| 11:15 AM | The next level of efficiency for mechanical joining systems | Dr. Marcus Matzke, Tox Pressotechnik GmbH & Co. KG, DE |

| 11:45 AM | New self-piercing riveting bolt for high performance mechanical joints in thin car body parts | Dr. Markus Hirschmann, Richard Bergner Verbindungstechnik GmbH & Co. KG, DE |

| 12:15 PM | New fastener invention for structural aluminium joining | Dr. Paul Briskham & Lewis Jepps, Atlas Copco IAS UK Ltd, UK |

| 12:45 PM |

Meet the speakers | Lunch Break |

|

Laser innovations |

||

| 2:00 PM | Machine-learning-assisted 3D laser vision for quality inspection of resistance spot welds, resistance element welds, and self-pierce riveting | Prof. Dr. Yeongdo Park, Dong-Eui University, Advanced Materials Engineering Department, KR |

| 2:30 PM | Laser beam welding of AlSi-coated high-strength steels with ultrasonic superimposition | Christian Wolf, University of Kassel, Institute of Production Technology and Logistics, Department for Cutting and Joining Manufacturing Processes, DE |

| 3:00 PM | Achieving cost and weight savings for battery structures through laser welding without filler | Lutz König, Precitec GmbH & Co. KG, DE |

OEM conclusions |

||

| 3:30 PM | OEM Advisory Board experts on current challenges in car body joining technology | OEM Advisory Board experts |

| 3:45 PM | Farewell address and end of the conference | |

Program is subject to change: Status April 10, 2024

Participants

Review

Flashback 2024

Flashback 2023

Your Contacts