Car Body Parts: Materials and Forming Processes 2025

The whole picture

For the second time, Car Body Parts: Materials and Forming Processes, brings together Automotive Circle’s international network of both material and process experts, for our two-day congress on everything to do with the development and production of structural or outer skin car body parts. With its mixture of focus contributions in two-fold parallel sessions as well as keynote plenary presentations, established during its premiere in 2024, the congress aims to discuss progress in car body materials developments as well as car body part production processes, from panel forming to (mega)casting – and the relations between these two realms.

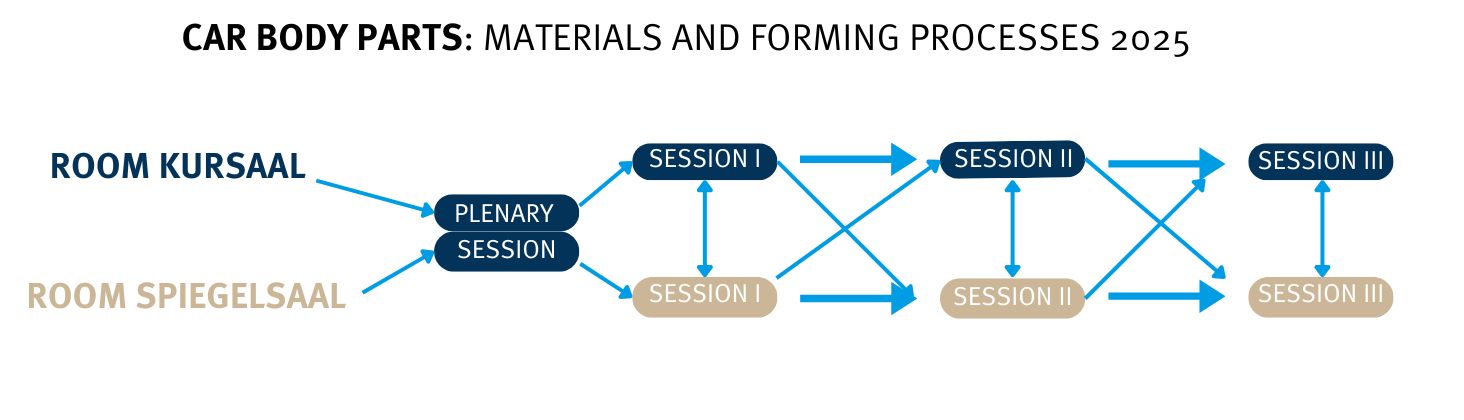

Overview of parallel congress sessions

Congress Program

| Time in CEST |

Kursaal |

Spiegelsaal |

| Plenary Session: Production Strategies |

||

| 8.00 | Welcome and conference introduction

Welcome and introduction Dr. Dirk Meine, Automotive Circle, DE |

|

| 8.15 | P1 Analysis of automotive innovation cycles and current trends in automotive production Prof. Alexander Schönmann, Technische Hochschule Ingolstadt / Technology Design and Application Automotive Manufacturing Foresight – Bavarian Foresight-Institute, DE |

|

| 9.00 | P2 MeGiCast: GigaCasting versus MultiMaterialMix front end structures – and the winner is? Hagen Wegner, FEV Consulting GmbH; Prof. Thilo Röth, Aachen University of Applied Sciences; DE |

|

| 9.45 | Meet the Speakers / Exhibition / Coffee and contacts | |

| Megacasting: New Materials and Process Solutions |

Panel Forming: Evolution of Hot Stamping |

|

| 10.30 | A1 The birth of a new aluminum alloy for structural parts Yvan Chastel, Renault SAS, FR |

B1 Innovative sheet metal manufacturing – sustainable and future production technologies for automotive components Jan Henning Risse, Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU), Institute of Manufacturing Technology (LFT), DE |

| 11.00 | A2 Mega/giga casting: a technological paradigm shift in die materials, component design and production technology Thibault Le Bourdiec, Rovalma, ES |

B2 The future of hot stamped parts at BMW Dr. Stephan Schirdewahn, BMW Group, DE |

| 11.30 | A3 Advanced die casting solutions for successful body in white applications Giovanni Poltronieri, Yizumi / Diecasting Engineering S.r.l, IT |

B3 Vacuum hot stamping technology with electro-galvanizing & high-temperature resistant lubricating coating Tony An, Pressler Advanced Forming Technologies, CN |

| 12.00 | Meet the Speakers / Exhibition / Coffee and contacts | |

| Megacasting: Mastering Production and Quality |

Panel Forming: Advanced Tooling and Surface Solutions |

|

| 1.15 | A4 Giga Press: the story behind the growth of diecasting in automotive BIW, where the technology is today and where it’s taking us tomorrow John Stokes, IDRA Srl, IT |

B4 Application of 3D-printed metal insert tools for automotive stamping dies Orhan Bibika, Ford Otomotiv Sanayi A.Ş; Mustafa Sevimli, SLM Solutions, TR |

| 1.45 | A5 GIGA casting production process and quality control Jisong Zhao, Duoli Automotive Technology (Chuzhou) Co., Ltd., CN |

B5 Increasing the service life of press hardening tools with the innovative EvolutionClad 58 coating solution using Laser Metal Deposition Andreas Bartling, voestalpine Additive Manufacturing Center GmbH, DE |

| 2.15 | A6 The role of die enterprise in developing integrated car body parts Zhenjin Liang, Guangzhou Die and Mould Manufacturing Co., Ltd., CN |

B6 (Hot) Stamping Out Body Shop Complexity & Driving Down Costs Paul Belanger, Gestamp, US |

| 2.45 | Meet the Speakers / Exhibition / Coffee and contacts | |

| Megacasting: Optimizing Physical and Virtual Processes |

Panel Forming: Innovative Forming and Line Concepts |

|

| 3.30 | A7 From straightening to savings: How intelligent systems optimize TCO of megacastings Norbert Meinikmann, Laubinger + Rickmann GmbH & Co. KG, DE; Martin Hartlieb, Viami Inc., CA |

B7 Technical Study for Deepless and Bottom-up Tension Fusion Press Forming Process Jeongho Kim, Hyundai Motor Company, KR |

| 4.00 | A8 Application of virtual casting tools in ultra-large aluminum casting development Qigui Wang, Andy Wang, General Motors Company, US – online presentation – |

B8 Space-saving line concept for hot stamping of large car body components Jens Aspacher, Schuler Pressen GmbH, DE |

| 4.30 | A9 Unlocking performance: overcoming challenges in large structural castings with advanced simulation solutions Vanessa Glück Nardi, Kai Beckmann, MAGMA Gießerei-Technologie GmbH, DE |

B9 Development of a machine learning-based verification and prediction model for addendum design in press forming Keungin Lee, Hyundai Motor Company, KR |

| 5.00 | Plenary assembly in room Kursaal | |

| Plenary Session: OEM material concepts | ||

| 5.10 | P3 Assessment of Exposed Aluminum Surface Undulations Using Non-Destructive Quantitive Metrics Adam Hodges, General Motors Company; Tamer Girgis, Commonwealth Rolled Products; US – online presentation – |

|

| 5.40 | P4 Way to zero – sustainable car body concepts Dr. Chris Frohwein, Dr. Matthias Graul, Volkswagen AG, DE |

|

| 6.10 | Meet the Speakers / Exhibition / Get together | |

| 7.00 | Networking Barbecue | |

(Plenary Assembly in room Kursaal)

| Time in CEST |

Kursaal |

Spiegelsaal |

| Plenary session: | ||

| 8.00 | P5 Standardization of steel sheet for automotive applications in a global context Klaus Unruh, Faurecia Autositze GmbH/ Verband der Automobilindustrie, DE |

|

| 8.45 | Exhibition / Coffee and contacts | |

| Developments in the Roll Forming Process |

The Digital Path to Stamping Excellence |

|

| 9.15 | A10 Steel body concept for future mobility to reduce carbon emissions Dr. Jongcheol Park, POSCO, KR |

B10 Automation of quality control in press lines at Renault Palencia plant Juan Carlos Garcia, Eines Vision Systems, ES; Philippe Lautridou, Groupe Renault, FR |

| 9.45 | A11 Recent developments in roll forming high strength aluminum Dr. Axel Förderreuther, Novelis Deutschland GmbH, DE |

B11 Holistic Digital Solution for optimized Sheet Metal Part Production Leopold Pöcksteiner, coilDNA GmbH, AT; Dr. Apostolos Papaioanu, iLARIZ GmbH, DE |

| 10.15 | A12 Resource-efficient part manufacture enabled by roll forming through digital tools Dr. Cornelia Tepper, Christoph Grüllich, Dreistern GmbH & Co. KG, DE |

B12 Incorporating tool and press deformations in stamping simulations to enhance part quality assurance Mark Vrolijk, Keysight Technologies, NL |

| 10.45 | Meet the Speakers / Exhibition / Coffee and contacts | |

| Rethinking Body Structures: Novel Materials |

Processing High-Strength Steels |

|

| 11.15 | A13 Woodflow in Motion – laying out car body structures with a natural and tunable material Denis Schmitz, creangineering, DE; Jorge Christie, Strong by Form GmbH, DE |

B13 High-ductility PHS1500, a game changer for energy absorption Ludovic Dormegny, ArcelorMittal Global R&D, DE |

| 11.45 | A14 Sustainable 6xxx aluminium with optimized surface properties & durability for the automotive industry Mustafa Melih Aksuoglu, Elizabeth Szala, Aluminium Duffel BV, BE |

B14 Streamlining indirect press hardening: a lean approach for galvanized steel without shot blasting Ernst Dietmar Schachinger, Dr. Kerstin Haider, voestalpine Stahl GmbH, AT |

| 12.15 | A15 Aluminium as game changer – sustainable lightweighting solutions for future vehicles Dinesh Thirunavukkarasu, Norsk Hydro ASA / Hydro Aluminium, NO |

B15 Development of UHSS TWB Side Sill Using Die Control System to Minimize Spring-back Dae Young Kim, Hyundai Steel, KR |

| 12.45 | Meet the Speakers / Exhibition / Lunch break | |

| Digitalization and Advanced Forming Solutions |

High-Strength Steel Developments | |

| 2.00 | A16 Breakthrough hot forming process to produce an ideal single piece battery tub Dr. Axel Förderreuther, Novelis Deutschland GmbH, DE; Dr. Peter Amborn, HoD Forming GmbH, DE |

B16 Development and application of advanced high-strength steel for automotive safety Sunhwan Kwon, Hyundai Steel, KR |

| 2.30 | A17 The Digital Coil as a solution for increased fluctuations in secondary materials Lucia Ortjohann, RWTH Aachen University, Manufacturing Technology Institute ( MTI), DE |

B17 Chain die forming of novel 1.9GPa tensile strength steel Sarah Tedesco, General Motors Company, US – online presentation – |

| 3.00 | A18 Data-driven modeling of forming effects for crash simulations Ingolf Lepenies, Scale GmbH, DE |

B18 Balancing global and local formability properties through Nb microalloying Prof. Hardy Mohrbacher, Niobelcon BV, BE; Bernardo Barile, CBMM Europe BV, NL |

| 3.30 | Plenary Assembly in room Kursaal | |

| 3.35 | OEM conclusions Members of the Advisory Board on their congress summary and future outlook in Car Body Part development and production |

|

| 4.00 | Farewell address and end of the congress | |

Program is subject to change

Status as of June 23, 2025

Participants

More Information

Review

Impressions of Car Body Parts: Materials and Forming Processes 2024

For more information on Car Body Parts: Materials and Forming Processes 2024 (e.g. Agenda, participants), take a look here!

Your Contacts